Research and development

- About us

- Research and development

Understanding materials leads to new discoveries.

Shachihata's policy is to create things from scratch.

This is the nerve center of Shachihata, where we apply creative thinking and perseverance to researching materials used in the company's products. Whether working on physical materials or electronic fonts, state-of-the-art facilities support our pioneering spirit in research and development.

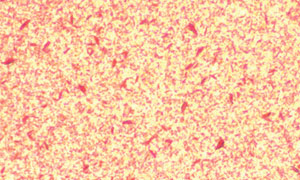

Nanotechnology Research

We succeeded in developing stable pigment molecules just one-millionth of a millimeter in size. The finer the molecule the faster it permeates paper and dries. But it will also bleed more easily, so we employed proprietary blending technology to prevent bleeding. We have already been able to produce stamp pads and vermilion inkpads for seals while working on other applications.

New Materials Development

We use microfiber for the fabric that covers the stamp pad to improve ink absorption. This allows ink to adhere evenly to the seal face using just light pressure. We also developed rubber materials for the ink absorbing part of the stamp that is suited to the ink's properties, as well as material for the body of the stamp. This was the result of much trial and error using silicon and polyethylene materials, aiming to achieve sufficient clarity and durability.

Font Development

We developed, in-house, the sharpest-looking fonts for stamping. We adjusted the balance of left-side and right-side character radicals so that they would not blur even on small seals. The font designs eliminate all wasted space. We offer several typefaces including Mincho and Gothic, and we inspected the shape and weight of the left-side and right-side radicals for each character to produce a beautiful stamp face.

3D CAD and 3D Printers

A 3D printer is connected to a 3D CAD system to automatically print three-dimensional prototype models with the design software. The combination greatly reduces the time required to produce a prototype and speeds up development dramatically. In addition, prototypes of Shachihata products are developed in-house. The entire process has been sped up, from the active use of cutting-edge equipment for development and design to bringing products to market.

Joint Research with Universities

In the area of research and development we are carrying out broad-based collaborations with various industries and university research organizations. We actively exchange information with these research organizations in order to expand the possibilities for new technological development. Much progress has been made in specific areas, particularly in the area of basic research, which has led to many examples of new materials being turned into products that can be mass produced.