Environment

- About us

- Environment

SHACHIHATA'S ECO ACTION CONCEPT

~For our Earth and our Future~

Environmental issues caused by excessive energy consumption must be dealt with immediately. Shachihata is dedicated to restoring balance in the global environment by stepping up its efforts to conserve and recycle resources and develop production systems that minimize industrial waste. Eco Action will remain a guiding principle in Shachihata’s operations now and for the foreseeable future.

Environmental Policy

Environmental Charter

As an enterprise that enriches people’s daily lives and culture, Shachihata regards environmental preservation as a corporate responsibility and is dedicated to the realization of a low-carbon society.

We also seek to provide environmentally friendly products and services with a low impact on the environment in line with its basic philosophy of balancing the needs of the environment with corporate activities.

Guiding Principles

- We shall seek to create products that enrich people’s lives and culture while finding the optimal way to manufacture them from the standpoint of the preservation of the global environment.

- We shall make our environmental activities a management priority and encourage all employees to do their utmost to support these efforts.

- We shall set our own standards for eco action and take steps to prevent the further destruction of the environment. In addition to adhering to relevant laws,regulations and other requirements.

- We shall undertake periodic reviews of our environmental practices and standards with the aim of sustaining progress made in preserving the environment.

- Steps shall be taken to make our environmental policies known not only to all employees but the general public as well with the goal of cultivating a shared understanding among all.

Regulation

1. Manufacturing meets current regulations

Shachihata is manufacturing products under strict Global regulations of chemical substances from the planning of material composition to the shipping. We are also a Green Partner with some electronic and electrical equipment manufacturers.

RoHS

Shachihata follows directives of the European Union that restricts the use of certain hazardous substances in electrical and electronic equipment. Our products are widely used in the production process of manufacturers of such products.

REACH (SVHC)

Shachihata reviews regulations for manufacturers and importers by gathering information on the properties of chemical substances, in order to protect people’s health and environment.

ELV

Shachihata products are widely used in the production process of car manufacturers as marking tools which meets the End of Life Vehicles Directive.

GHS

Shachihata provides by SDS the correct information about the potential dangers of chemical products according to Globally Harmonized System of Classification and Labeling.

Shachihata is adopting original regulation of environmental investigation.

[Example] Flow of chemical substances of purchased materials

- Selection of manufacturer of material

- lnspection of controlled substances

- Verification of analytical data

- Registration of analytical data

- lncoming inspection

- Acceptance validation

Shachihata is compliant with various chemical survey sheets which are required by many types of industries, countries, and organizations (such as the EU), and is able to submit the documents.

- SDS(Safety Data Sheet) Japanese/English

- JIG (Joint Industry Guide)

- JAMP chemSHERPA

- JAMA (Japan Automobile Association) sheet

- GADSL (Global Automotive Declarable Substance List)

- Declaration of Non-use of RoHS / halogen/SVHC /phthalate ester/ PFOS

- Other particular inspection sheet

Reduce

2. Manufacturing Long Life products

Long-lasting is one of our core concepts in research and development. We offer a full line-up of refillable markers, stamp pads, and pre-inked stamps.

Reuse

3. Ecology system good for people and the environment

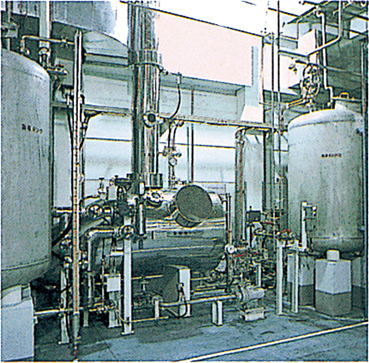

Shachihata conducts eco-friendly manufacturing at each factory.

Example: lnazawa (Japan) factory

-

Ink solvent recovery system

-

Waste water regenerating system

ISO9001/ISO14001 : RESEARCH&DEVELOPMENT, PRODUCTION HEADQUARTER

Recycle

4. Manufacturing that is good for the environment...ECO-GREEN

Shachihata has released a line of ECO-GREEN products made from recycled and other materials of a low impact on the environment with the realization of the action that must be taken by the manufacturer.

|

CATEGORY |

ITEM CODE |

RECYCLED PLASTICS |

PERCENTAGE OF RECYCLED PLASTICS* |

|

Xstamper |

CD-AEC(0)・CD-AEC(1) |

RECYCLED ABS, RECYCLED POM, RECYCLED PET |

65% |

|

CD-BEC/S |

RECYCLED ABS, RECYCLED POM, RECYCLED PET |

64% |

|

|

CD-BEC/MS |

RECYCLED ABS |

68% |

- Percentage of recycled plastics weight in the total of the plastic, not including the ink weight.

Refine

5. To prevent global warming

Shachihata has been conducting Carbon Offset (in Australia) to prevent global warming.

Carbon Offset

Artline has purchased carbon credits in global hydroelectric power generation. So Artline 70, 90, 700 and 100 permanent markers, and 200 writing pens are doing their bit for the environment.